Lean Product Development

Lean Product Development Training in South Africa

Capture the Potential of Lean Thinking

Learn essential strategies and key tools that will decrease

time-to-market, reduce waste, streamline product development

processes, enhance product quality, and fully integrate new product

designs into a Lean production environment.

This five-day program trains product development engineers and new

product team members in Lean concepts, tools, and methods essential

to the Toyota Product Development System (TPDS). Each day offers a

set of learning objectives that enable participants to understand

and appreciate the Lean product development process and its tools.

Collectively, these objectives prepare participants to implement

Lean development in their organization. course advisors can supply details about our current and upcoming specials, our publicly scheduled Six Sigma or Lean Six Sigma classes or about our in-house and bespoke training. Our consultants can be contacted by email or on phone number +27(0)21 426 5300.

Note that this course does not run

without the minimum required delegates which is 7.

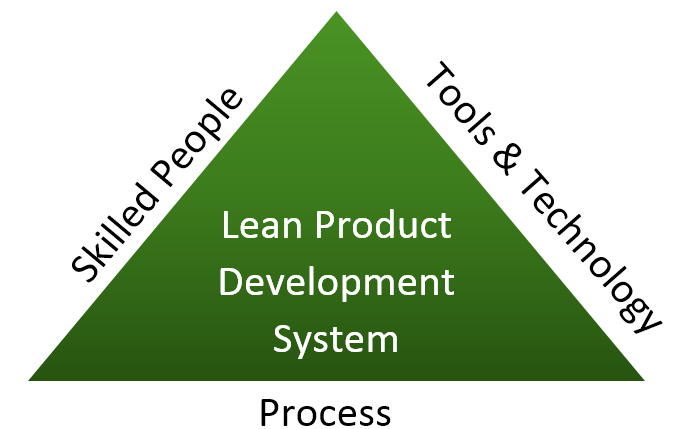

Lean Product Development Program Components

Overview of Lean Product Development

Introduction to the Toyota Product Development System: How It Works

and Key Benefits

Problems with traditional product development

Overview of workflow within a lean product development system

The role of the customer, employees and organization

Traditional Lean Product Development

Simulation

Illustrates typical wastes

Tracks metrics associated with traditional wastes

The Lean Tools of Toyota Product

Development System

Principles of Nemawashi

Principles of Ringi

Creating effective A3 reports for Lean Product Development

Hoshin management

Lean Value Stream Mapping for Lean Product

Development

Introduction to value stream mapping

Mapping the current state

Lean product development principles

Mapping the future state

Creating an implementation plan

Survey of Advanced Design Tools in a Lean

Product Development System

Error proofing

Process for systematic error proofing

Definitions and applications

Tools for Lean Launch and Implementation

Planning

Introduction to the 3P

Lean Manufacturing Cell Design

Material Flow Planning

Lean Part Presentation

Lean Product Development

Simulations

Apply lean tools and techniques to the product development process

Track the metrics and realize the impact

Check out our new Lean Six Sigma Training website

Check out our new Lean Six Sigma Training website